There are many electrical connectors that can be important for everyday life. These can be classified in many ways, but throughout this post we will focus mainly on high current and high voltage electrical connectors.

Each of these has very different properties and we will treat them separately in order to explain their characteristics and the market orientation that each of them should have.

High current and high voltage connectors

High intensity electrical connectors

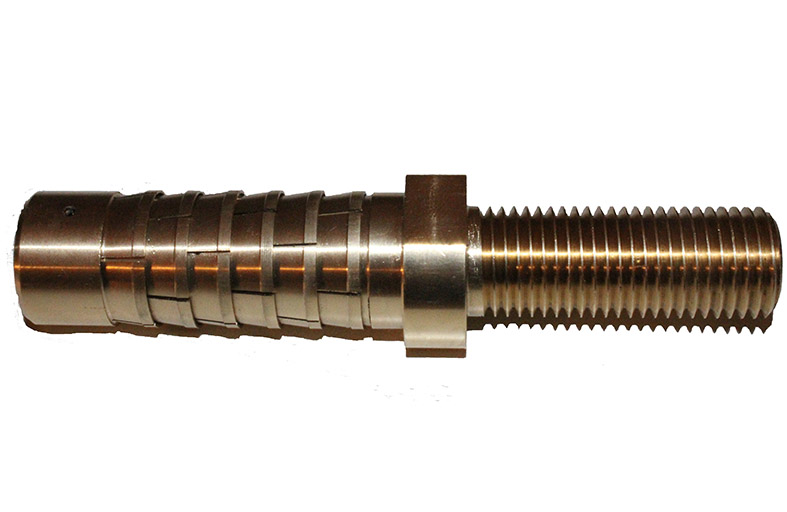

High current contacts are well suited for applications where more than two spring loaded contacts are used. They have basic designs with smaller sizes, which means that material costs are very low, even though the effectiveness of the connectors and their high level of performance are maintained.

This type of connector is used for very high power contacts. Hence, they are actually used in switches, bushings, disconnectors, switches and circuit breakers. This type of connection is a continuous development process in order to be able to offer safe, high-powered contact solutions.

This design combines mechanical and electrical properties that have been improved to offer the significant ability to conduct high current currents with a constant low resistance. In addition, the contact area ensures minimal heating, even under constant load.

The most important advantage of high-current electrical connectors is the tolerance compensation, as it is a flexible connector and provides the manufacturer with a wide variety of contact solutions.

High-current contacts require 25 to 1000 Amps (A) in steady state situations.

High voltage electrical connectors

This type of high voltage monopole connector can withstand a maximum of 25 KV in permanent operation.

They are designed to combine great ease of installation with high performance in all conditions. Its operation also ensures that it will be very good even at temperatures below those of the connected conductors.

High voltage electrical connectors when used must meet both the electrical and mechanical requirements used for other technical connections. In addition, it must be ensured that they will not produce the dreaded “crown effect“. This occurs on the surfaces of the circular section conductors, where, due to the ionization of the air, high potential differences are generated, which causes the appearance of a corona-shaped halo of different colors. The intensity of this effect can be quantified according to the colour produced, being reddish in mild cases and bluish in more severe cases.

As we have seen in the previous paragraphs, high current and high voltage electrical connectors are widely used today in various industrial sectors. For this reason, it is necessary to know them well, both in terms of their use and their production.