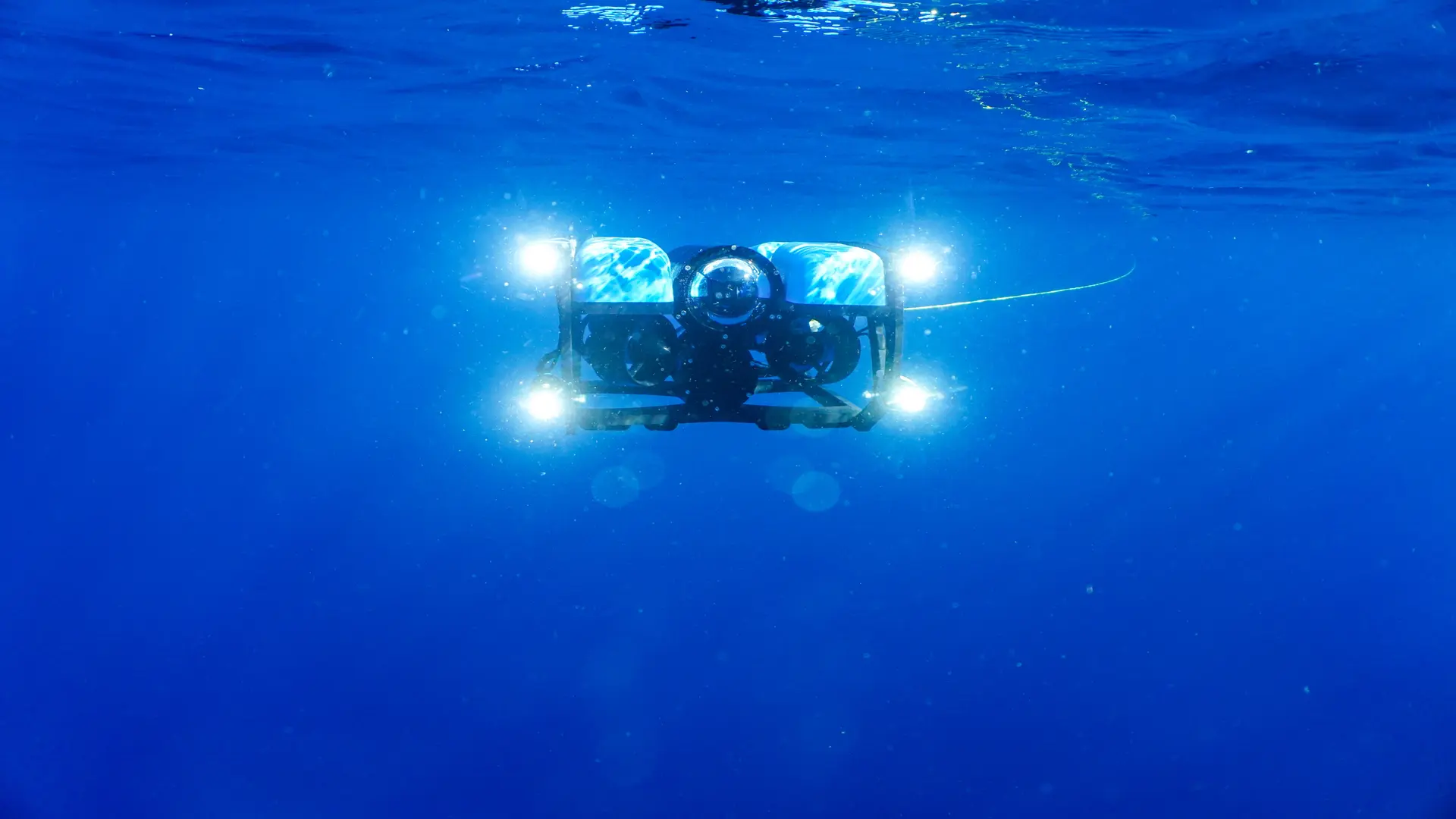

When we think of global connectivity, the first things that come to mind are Wi-Fi, satellites, or mobile coverage. However, the reality is quite different: 97% of global communications travel through subsea cables. These cables, which cross oceans connecting continents, rely on critical components such as subsea connectors to ensure their proper operation.

What is a subsea connector and why is it so important?

In order for these connectors to function properly thousands of meters below sea level, they must withstand extreme conditions, including:

-

Pressure of up to 600 atmospheres (equivalent to 6,000 meters depth)

-

Corrosion caused by saltwater

-

Constant low temperatures

-

Natural threats such as tsunamis, as well as the presence of marine life or sabotage risks

Only a handful of certified subsea connector manufacturers possess the technical capabilities and experience required to meet these challenges.

ALFA’R: New Certification for Extreme Environments

At ALFA’R, we’ve spent over 60 years developing industrial connectivity solutions, and we’ve applied all that know-how to a specialized line of certified subsea connectors, designed to withstand the most demanding marine conditions.

Our connectors:

-

Tested and certified by the National Oceanographic Center (NOC) in Southampton (UK)

-

Capable of operating at depths of up to 6,000 meters

-

Custom-built, allowing the integration of signal, power, and fiber optics according to client requirements

-

Made with high-strength materials to ensure durability, watertightness, and reliability

Thanks to their modular and customizable design, they can be applied in:

-

Subsea communication systems

-

Offshore energy (wind and gas)

-

Oceanographic research

-

Naval defense and security

Why choose a certified manufacturer?

Choosing certified subsea connectors ensures:

-

Operational safety in hostile environments

-

Technical compatibility with next-generation equipment

-

Long-term durability, reducing failures and maintenance costs

-

Regulatory compliance for international projects

In contrast, using uncertified copies or low-quality connectors can compromise an entire critical infrastructure.

ALFA’R: Your Technology Partner for Connectivity in Harsh Conditions

We connect more than just cables. At ALFA’R, we develop tailor-made engineering solutions for sectors where there is no margin for error.

If you’re looking for a certified subsea connector manufacturer, get in touch — we’ll be happy to help take your project to the depths.